Theory of Constraints, Critical Chain Project Management, Lean : industry consulting & training - Marris Consulting

Theory of Constraints in production

What are the origins of the Theory of Constraints?

The Theory Of Constraints (TOC) was popularized by the book “The Goal” written by Eliyahu Goldratt in 1984.

In this book, Eliyahu Goldratt explains that it is pointless in today's world to try to balance factories, there is always a capacity constraint somewhere in the system, also called a bottleneck. It has become nearly impossible to ensure that each part of the business / system has the right amount of work, neither too much nor too little.

In a "VUCA" world (Volatile Uncertain Complex Ambiguous), companies can no longer protect themselves against all the fluctuations, external and internal, by stocks since they increase inertia and risk to become obsolete.

Constraints are increasingly difficult to avoid. The Theory of Constraints (ToC) is therefore becoming more and more relevant.

Value-added content about the Theory of Constraints

Our newsletter:

If we simplify, the Theory of Constraints seeks to focus actions on bottlenecks, because these are the resources that determine the overall performance of the system.

The 5 focusing steps of the Theory of Constraints

The process of improving the theory of constraints is divided into 5 steps:

1. Identify the constraint of the system

Identifying the constraint (bottleneck) of the system is obviously the most critical step. How to implement The Theory of Constraints if you don't know where your constraint is?

2. Decide how to exploit the constraint

Exploiting a constraint is fairly easy: you focus the entire business attention on a single resource. Everyone loves to produce, and as much as possible, there are a lot of simple improvement levers to activate for visible and quick results.

3. Subordinate everything to the above decision

The hardest step in The Theory of Constraints. The difficulty with TOC is not the constraints but the non-constraints. Technically it sounds simple: production should only be started on the basis of the needs and the availability of the constraint. But this implies that we no longer ask other resources to work to their full potential (at their capacity) but according to the capacity of the constraint. The first condition is therefore to learn to stop overproduction at the level of non-bottlenecks. These no longer need to be running at full speed all the time.

4. Elevate the constraint of the system

This step of the Theory of Constraints is similar to step 2 "Exploit the constraint", except that step 2 does not require significant investment, in time or money, it is mainly a question of identifying actions with immediate effects, "quick wins".

Increasing the capacity of the system constraint is easy, but in some cases requires more investment, for example carrying out a SMED (Single Minute Exchange of Die) on the constraint. ROI (Return On Investment) is usually easy to justify since the impact on profitability or Throughput will be very significant.

5. Go back to step 1

Once the capacity of the constraint has increased, it is possible that it is no longer the constraint, so we must find the new constraint and start again the process of improving the Theory of Constraints.

At Marris Consulting, we advocate an almost identical approach, Management By Constraints, it differs from The Theory of Constraints on one point: the search for the "least worse" constraint (rather than a permanent constraints hunting). The goal is to eliminate the constraints one after the other until we get to the "least worse" bottleneck. In our opinion, finding the right imbalance of capacities is desirable.

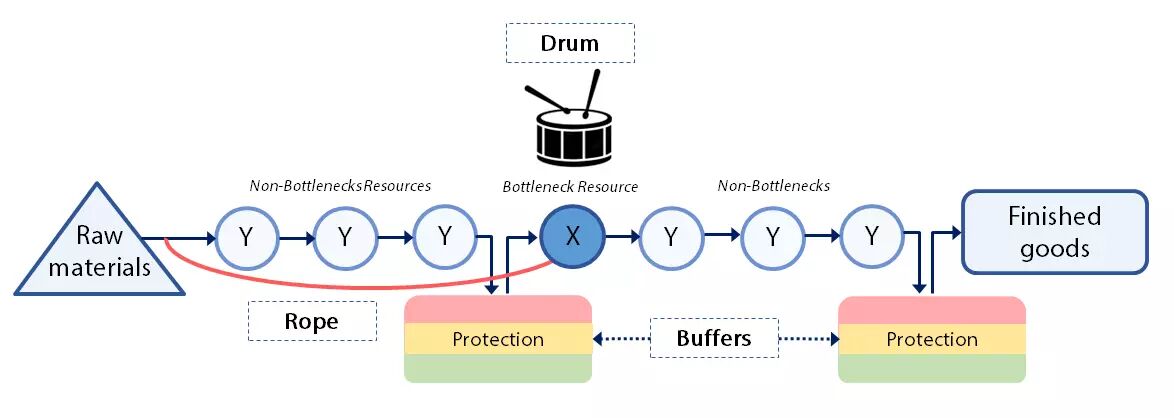

The Drum-Buffer-Rope System

The Drum Buffer Rope (DBR) is the flow management principle when there is a bottleneck, composed of 3 elements:

- The Drum = Bottleneck, the resource, setting the pace of the overall system,

- The Buffer = protection of the bottleneck and sales (throughput and on-time deliveries)

- The Rope = mechanism to launch work in the system, to set the level of work which will allow an optimal flow without congestionning the system with work in progress, based on the bottleneck capacity

Implementation of the Theory of Constraint with Marris Consulting

We start our Theory of Constraints (TOC) implementations by performing a quick, approximately two-day, performance diagnosis of your business, our goal is to identify the constraint (bottleneck), or confirm your suspicions, and build a roadmap enabling you to achieve your objectives, in particular through a better use of the constraint.

Once the constraint has been identified, we train the teams about the Theory of Constraints over a day, then we support them in implementing the actions identified during the diagnosis and in improving performance.

Note that we combine the Theory of Constraints with other approaches, such as Lean, so as to create the winning cocktail adapted to the issues of each company.

More articles on Theory of Constraints

Using Theory Of Constraints to boost Lean programs

Production: 6 signs you should consider managing your constraints

More about Marris Consulting, experts in Theory of Constraints consulting and training

Marris Consulting is an expert company in Theory of Constraints consulting and training. With over 25 years of experience, our consultants have gained a unique knowledge in implementing TOC in manufacturing and process industries. To this day, we have successfully completed over 270 transformation projects internationally.

The Theory of Constraints provides a broad and powerful set of tools to improve any process in your organization. By identifying bottlenecks and implementing the right actions, your company can grow its business and build a determinant and sustainable competitive edge. Our TOC consulting and training services will provide you with the most efficient path to implementing this approach, for a drastic transformation in your company’s performance. As experts in the field of management by constraints, we are well aware that each client’s scenario is unique, which is why we sometimes combine the Theory of Constraints (TOC) with other approaches such as Lean and Six Sigma to create a winning cocktail, perfectly adapted to your issue.

For more information about our services, please do not hesitate to contact our Theory of Constraints consultants.

What are the benefits of the Theory of Constraints?

The Theory of Constraints (TOC) is a management philosophy that aims to improve the overall performance of an organization by identifying and managing its constraints. Divided into 5 steps, it offers several key benefits that contribute to the efficiency and effectiveness of an organization's operations:

-

First, TOC helps in prioritizing and focusing on the most critical issues within a system, thereby enabling resources to be allocated efficiently. By identifying and resolving constraints, the Theory of Constraints facilitates smoother workflow and eliminates bottlenecks, enhancing productivity and reducing lead times.

-

Secondly, the Theory of Constraints encourages a holistic approach to problem-solving, within a system. This approach promotes a deeper understanding of the cause-and-effect relationships within an organization, enabling a more comprehensive and integrated decision-making process.

-

Furthermore, TOC encourages the application of continuous improvement principles, enabling organizations to adapt and evolve in dynamic environments. The Theory of Constraints helps organizations remain competitive and responsive to changing market demands by implementing a culture of ongoing learning and adaptation.

-

Additionally, the Theory of Constraints promotes the optimization of resource utilization, allowing organizations to make the most efficient use of their available resources. This leads to cost savings and improved profitability, as resources are channeled towards activities that directly contribute to the organization's goals and objectives.

-

Overall, the benefits of the Theory of Constraints in manufacturing include improved operational efficiency, enhanced decision-making capabilities, adaptability to changing environments, and optimized resource utilization, all of which contribute to an organization's long-term success and sustainability.

About Marris Consulting

Marris Consulting is an industry consulting and training company specialized in the Theory of Constraints (ToC) and Critical Chain Project Management. We focus on improving the performance of manufacturing and process industries by using Constraints Management combined with Lean and Six Sigma. To boost project performance, we also use Critical Chain Project Management (CCPM), which we sometimes combine with Lean Engineering. Our 2-day performance audits, our performance consulting services and our project management, Lean, ToC & CCPM training by our industry consultants offer a wide range of solutions to help our clients around the world reach the highest possible levels of performance.