Theory of Constraints, Critical Chain Project Management, Lean : industry consulting & training - Marris Consulting

The Theory Of Constraints: to accelerate your Lean program and generate growth

By focusing Lean initiatives in the right places within the company the Theory Of Constraints leads to much faster improvements in performance. By identifying what limits sales, TOC enables organizations to renew with growth and avoid downsizing. You could call it focused Lean.

Point of view written by Philip Marris, Founder and CEO of Marris Consulting based in Paris, a specialist in Theory Of Constraints (TOC) and Lean and author of the French reference book on applying TOC to manufacturing and process industries Le Management Par les Contraintes en gestion industrielle[1].

The Theory Of Constraints (TOC)

The main approaches to improve the performance of industrial organizations are Lean, Six Sigma and the Theory of Constraints. TOC is the least well known and the least used. It is sometimes referred to as Constraints Management. This school of thought was developed by Eliyahu Goldratt in the 70's and became known in particular through a worldwide bestseller novel – The Goal [2] – that has been sold over 7 million copies in 29 languages. It assumes that all plants are now unbalanced, the workload is unevenly distributed. At any time there are overloaded resources – bottlenecks or constraints – and "non-bottlenecks”. Management rules must be redesigned accordingly.

Lean or Toyota’s way

To avoid confusion we consider here that "Lean" is the approach developed by Toyota.[3] It is a long term process of eliminating waste, a process of continuous improvement implemented by all employees. It seeks to continuously, uncompromisingly, improve products flow. The Lean manufacturing system is now quite well understood, very frequently identified as a goal…and sometimes quite well copied. We believe that it is unfortunate that in the majority of cases Toyota’s R&D and new product development system is not also copied since it is a very important component of the Toyota “model”, people buy their cars as much for the way they are designed as for the way they were built. What is most disturbing is that when the ex-first world copies Toyota, it nearly always leads to a process of continuous downsizing whereas Toyota is a growth and full employment model. We call this company contraction “improvement process” laced with Japanese words “Bad Lean”.

TOC + Lean: winning combination

When Lean and Theory Of Constraints are combined, improvements are much faster and significant increases in sales are frequently observed. Lean drives out wastes and TOC identifies constraints on which to act to increase turnover. The combination of the two creates a virtuous circle whereby the company becomes continuously more effective by eliminating the added expenses, and simultaneously generates additional sales that can absorb the productivity improvements.

TLS: TOC + Lean + Six Sigma

The third major approach today is Six Sigma. It aims at reducing variability in the processes. Its 2 main components are DMAIC (Define, Measure, Analyze, Innovate/Improve, and Control) and an implementation system based on certified experts (Green Belts…Master Black Belts). Its major differentiating factor is probably the importance attributed to collecting and analyzing data and doing Design Of Experiments (DOE) to minimize variability. Since the year 2000 Lean and Six Sigma have been frequently united as “Lean Six Sigma”. TOC, Lean and Six Sigma can be combined hence the “TLS” label. The compatibilities or incompatibilities between the 3 are the subject of unending internet discussions mostly among consultants. TLS, or TLSx, is meant to symbolize an open mindset and avoidance of quarrelling between the approaches or sects.[4] You keep an open-mind and you mix your own cocktail according to the problem to solve and your personal experience.

An example

Let’s take for example, a production unit of steel sheets. The plant is large - more than 1,000 people - and includes several stages of production: steel smelting, continuous casting, rolling, heat treatment and surface treatment, then cutting. The initial production cycle was 30 days.

First step: increase the turnover

An analysis of the plant located the bottlenecks. In this type of process industry, identification of the constraint is easy because Work In Progress accumulates in front of the bottlenecks. In this case, the heat treatment furnaces were the bottlenecks: the turnover is determined by these equipments. Each hour lost on these ovens is an hour of lost sales for the company. Therefore we must focus all improvement efforts on that part of production. In this way, without investing but just applying simple solutions, the throughput of the furnaces was increased by over 20%:

-

Improvement of curative and preventive maintenance of these bottlenecks by giving them priority over other equipments,

-

Reduced changeover time by compressing the cooling time with the use of cold steel sheet "martyrs" (“Process SMED”),

-

A decrease in the number of changeovers per week thanks to an appropriate scheduling,

-

Elimination of most of the rework by better process mastery (simple Six Sigma).

In this way the productivity of the whole 1,000 people factory was increased by 20% in 3 weeks.

Second step: Synchronize the factory to the rhythm of the bottleneck

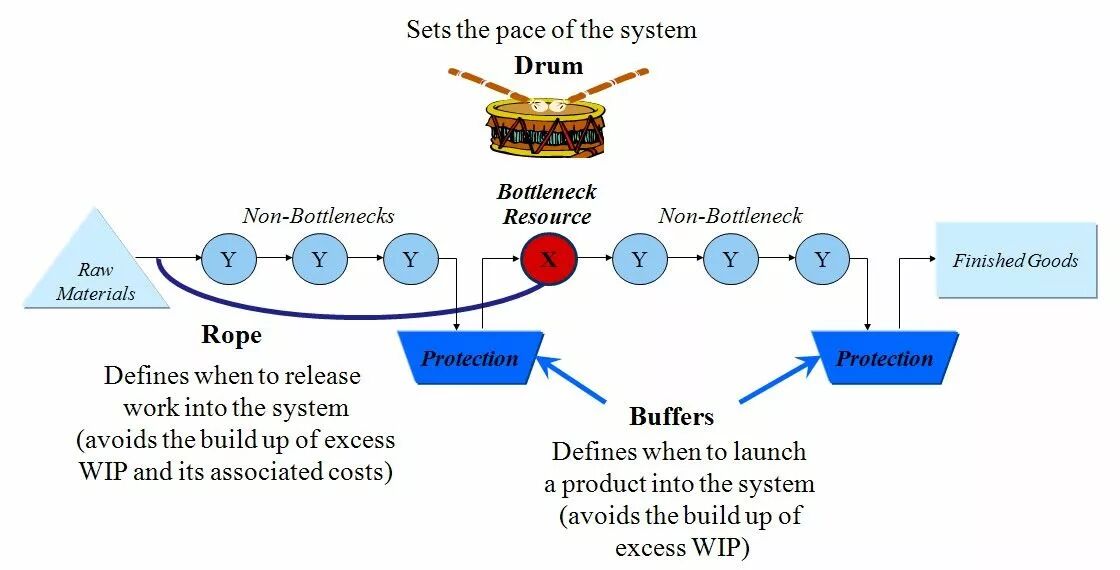

The flow of the plant must be controlled and driven in accordance with the bottlenecks. The TOC system is called "Drum - Buffer - Rope" or DBR:[5]

- Drum: Optimized scheduling of the bottlenecks to maximize their output,

- Buffer: Protection of the bottlenecks with buffers so that upstream problems on non-critical resources don’t starve these critical resources, and to ensure on-time deliveries, implementation of a buffer before shipment,

- Rope: Launch new work orders according to the bottlenecks' capacities.

The DBR system has demonstrated its ability to reduce WIP by 50 to 80%. Furthermore it is a nearly universal system applicable to all sorts of production systems. In the present case WIP and lead times immediately dropped by 50% from 30 to 15 days including 6 days of buffers in front of the ovens.

Drum - Buffer - Rope : The product flow control logic of the Theory Of Constraints

Drum - Buffer - Rope : The product flow control logic of the Theory Of Constraints

Third step: focus the improvement process – focused Lean

Once DBR is implemented, it is imperative to continuously observe the contents of the buffer. The lateness of arrivals was analyzed to identify the major upstream problems, it permitted to set the priorities of the improvement actions. In our example, it highlighted two activities that were responsible for the worst delays:

-

An old shearing machine in a corner of the factory with frequent breakdowns of several days,

- Metal samples that were frequently late because the testing laboratory lacked rudimentary priority management.

Once these issues had been resolved, the plant was able to reduce the buffer from 6 days to 4 days. It took 3 weeks and an investment of 9K€. By solving those two "small secondary problems” which were actually the most damaging for the plant, the entire manufacturing cycle was reduced from 15 to 13 days. This process of continuous improvement, guided by the analysis of the buffer stock is then repeated continuously (endlessly). This is a relatively unknown facet of the Theory of Constraints: do not ignore the "non-bottlenecks" (which are maybe 90% of resources in a factory!). Consider them in a different way; they cannot contribute directly to the level of short term sales but they have an important role to play.

Maintain the virtuous growth spiral to avoid continual downsizing

In the above example, in just a few weeks, the productivity of the company was increased by 20% and the production lead times were reduced by 50%. The next step was to exploit this new performance and increase the volume of sales to absorb the newly available capacity. This is critical to avoid the pressure of headcount reductions which would destroy the process of ongoing improvement by stifling the motivation of the employees to further improve. The goal is to maintain “good”, focused Lean (a growth model) and avoid “Bad Lean” (continual downsizing).

TOC is applicable to all departments of the company and the constraint might not be in production

In the case presented here, producing more was sufficient to sell more. This is currently not the case in many companies who suffer from insufficient demand for their products. In this case the basic reasoning remains the same but the Theory of Constraints considers that the market is never really the constraint. Weak market demand is the consequence of a weak product and/or service offering. The company must identify where its internal constraint really is. It could be in Engineering if the products are of inferior quality (specifications) than those of the competition. It could be in the Marketing or Sales departments if the company has good products but the market is not buying them in sufficient quantities. In these cases it is recommended to reconsider the company’s strategy and tactics using for instance the Thinking Process of TOC.[6]

For further information, follow or participate in discussions in the LinkedIn TLS group and stay informed about the latest news of the TLS community with TLS Scoop.it!.

About the author

Philip Marris is CEO of Marris Consulting based in Paris. Over 80% of the firm’s projects are based on Theory of Constraints, "TOC + Lean" or TLS. He is the author of the French reference book Le Management Par les Contraintes en gestion industrielle. He is the founder of the LinkedIn “TLS – TOC, Lean and Six Sigma” group. He is active in increasing the awareness of Theory of Constraints in Europe. He is a member of the Advisory Board of the TOC Institute India. He started his Theory of Constraints journey in 1986 when he worked with Eli Goldratt. He started his Lean journey in 1984 and has been trying to better master Lean ever since. He has over 35 years of experience in industry and in consulting. He is English and is bilingual and bi-cultural English - French.

More about the combination of Lean and Theory of Constraints in manufacturing

Marris Consulting is an expert company in the field of Lean manufacturing and Theory of Constraints consulting. With more than 25 years of experience in combining Theory of Constraints (TOC) with Lean, we are convinced that this integrated approach leads to faster and more significant performance improvements in the manufacturing and process industries. The combination of Lean and TOC creates a virtuous circle: the Theory of Constraints is a highly effective mechanism to identify the constraints on which to act, while Lean manufacturing provides a rich toolbox of improvement techniques. The company then becomes more competitive by eliminating waste in the parts of the system that are the greatest constraints, while generating additional sales.

With proven knowledge and significant experience in implementing TOC + Lean in manufacturing, our Theory of Constraints consultants provide you with the most efficient path to implementing this integrated approach, for a major transformation in your company’s performance.

[1] Le Management Par les Contraintes by Philip Marris, 2000. A textbook in French that describes in detail how to implement TOC in manufacturing and process industries. It suggests that it is important to choose the “best” bottleneck and organize excess capacity around it. See the dedicated website in French: www.management-par-les-contraintes.com.

[2] The Goal, A process of ongoing improvement, Eliyahu M. Goldratt and Jeff Cox, first published in 1984. This "business novel" was elected by Time Magazine in 2011 as one of the 25 most influencial business books of modern times alongside W. Edwards Deming and Taiichi Ohno.

[3] Lean or the Toyota Production System (TPS) or again the Toyota Way is now well documented. We recommend one recent book: The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer, 2003 by Jeffrey Liker.

[4] The first use of the term TLS is generally attributed to Reza (Russ) Pirasteh and Kimberley Clark in a article in the APICS May 2006 journal Continuous Improvement Trio : The top elements of TOC, Lean and Six Sigma make beautiful music together. It is the study of 211 improvement projects in 21 factories employing 45 000 people in which 89% of the gains are attributed to TLS, only 11% being generated by Lean or Six Sigma alone.

The best recent book on TLS is, we believe: Epiphanized: Integrating Theory Of Constraints, Lean and Six Sigma by Bob Sproull et Bruce Nelson, 2012. It is 2/3 novel and 1/3 textbook. It is strongly recommend especially as the first book to learn about TLS.

[5] DBR is the original system. More recently "Simplified DBR" or S-DBR has been developed for situations in which the capacity constraint is no longer in production (it is in Sales, R&D …). For more information about DBR and S-DBR see Manufacturing at Warp Speed by Eli Schragenheim and H. William Dettmer, 2001.

[6] See for example the books by William Dettmer such as The Logical Thinking Process, 2007

About Marris Consulting

Marris Consulting is an industry consulting and training company specialized in the Theory of Constraints (ToC) and Critical Chain Project Management. We focus on improving the performance of manufacturing and process industries by using Constraints Management combined with Lean and Six Sigma. To boost project performance, we also use Critical Chain Project Management (CCPM), which we sometimes combine with Lean Engineering. Our 2-day performance audits, our performance consulting services and our project management, Lean, ToC & CCPM training by our industry consultants offer a wide range of solutions to help our clients around the world reach the highest possible levels of performance.