Theory of Constraints, Critical Chain Project Management, Lean : industry consulting & training - Marris Consulting

Reduce the downtime of aircraft in aeronautical maintenance and support ramp-up in volume

Context

An aeronautical maintenance company for military aircraft wanted to reduce its maintenance durations. The average time before the implementation of Critical Chain Project Management (CCPM) was 2 to 3 years for the heavy maintenance and modernisation of an aircraft. The problems encountered by the company:

- Maintenance was not planned in any detail and not properly prepared before the arrival of the aircraft.

- There was no easy and reliable way to see the progress of an aircraft and estimate an end date.

- The execution of the work on a plane did not follow a logical sequence. The rule was to try to give work to everyone which caused waves of work.

- The Supply Chain as a whole was disorganized and chaotic. The lack of parts had a huge impact on the aircraft's Turn-Around-Time (TAT).

- The controllers seemed to be the bottleneck.

Furthermore, an improvement in operational performance was all the more necessary since the implementation of CCPM coincided with the beginiing of a big new contract which led to a huge increase in production volumes.

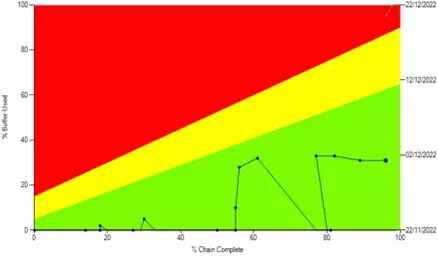

Maintenance monitoring with the Fever Chart

Approach

An in-depth diagnosis of the situation and the training of many people in Critical Chain Project Management applied to MRO was carried out. Following this, many actions were launched:

- Planning using the Critical Chain approach of all aircraft, following a logical sequence of tasks defined with the foremen.

- Preparation of maintenance before the arrival of the aircraft. Monitoring the progress of maintenance on a weekly basis and measuring progress using the Fever Chart.

- Analysis of the causes of buffer consumption, Improved kitting of parts and release of kits to production just-in-time according to the sequence of activities to be carried out.

- Creation of an operational support cell. A group of people guaranteeing complete compliance (parts and working documents) in support of production.

- Implementation of a load vs. capacity analysis of the different trades (mechanics, aircraft sheet metal workers, wing sheet metal workers, electricians, etc.).

Results

-

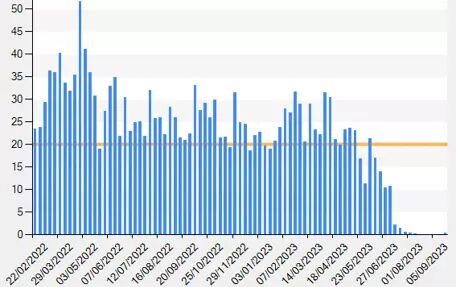

Reduction of aircraft downtime from more than 2 years on average to 13 months (a world record for this type of maintenance).

-

Clarity and stability in the priorities given by the management. Less chaos. Calmer work environment. The release dates of the planes are known in advance and piloted. Reduced number of missing parts.

-

Decrease in the lead time of certain internal logistics operations (receipt control) and cleaning up of obsolete stocks.

-

Implementation of a relevant workload/capacity analysis to build annual budgets, a valuable decision-making tool: recruitment plan (+60 in staff), use of subcontracting (identification of work that can be delegated to absorb the overload of 30,000 hours over 6 months, + 20 external technicians) etc.

About Marris Consulting

Marris Consulting is an industry consulting and training company specialized in the Theory of Constraints (ToC) and Critical Chain Project Management. We focus on improving the performance of manufacturing and process industries by using Constraints Management combined with Lean and Six Sigma. To boost project performance, we also use Critical Chain Project Management (CCPM), which we sometimes combine with Lean Engineering. Our 2-day performance audits, our performance consulting services and our project management, Lean, ToC & CCPM training by our industry consultants offer a wide range of solutions to help our clients around the world reach the highest possible levels of performance.