Theory of Constraints, Critical Chain Project Management, Lean : industry consulting & training - Marris Consulting

Implementation of the Theory of Constraints in production at SKF

Context

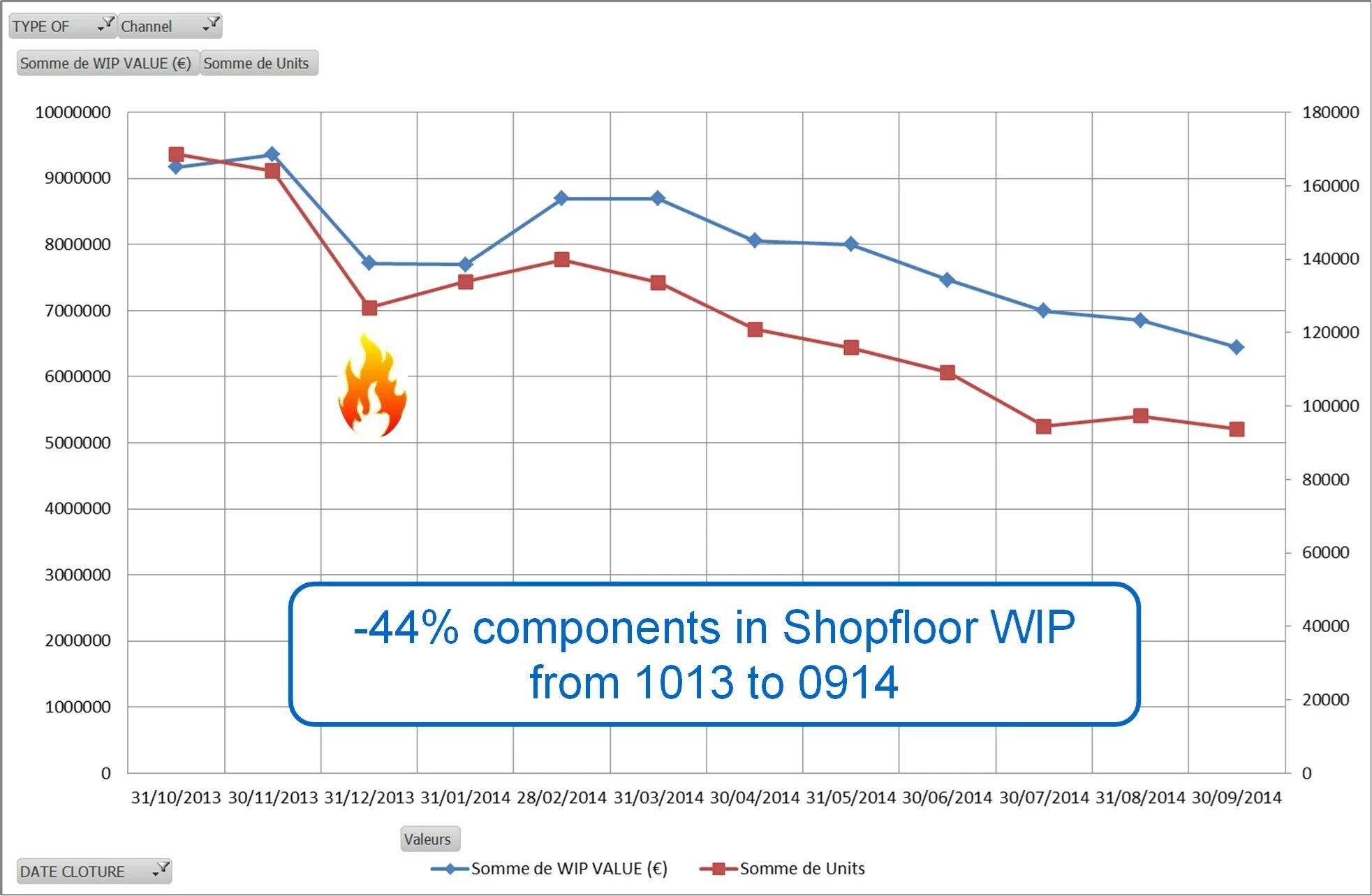

Confronted with a catastrophic fire that resulted in the extensive destruction of its work-in-progress inventory and inflicted damage upon critical machinery, the bearing manufacturer was compelled to cease workshop activities for a period exceeding five weeks. This situation quickly became dangerous for its customers, who could increase the supply of parts from competitors.

The manufacturer chose to implement the Theory of Constraints to ensure the most responsive service possible, guaranteeing deliveries with reduced lead times and minimized stock levels.

Objectives

- The company's primary objectives are centred on reducing inventory levels and enhancing the service rate.

Approach

- Identification and enhancement of skills related to bottleneck machinery, especially those used for drilling and broaching.

- Strengthening of personnel versatility.

- Increased mobilisation of support functions such as maintenance, engineering, and quality.

- Control of subcontractors

- Implementation of LEAN tools: daily meetings, SMED methodology to reduce tool change times, and the application of 5S principles for workplace organisation.

- 50% reduction in production launches.

- Readjustment of ERP parameters for improved production flow management.

- Subordination of the manufacturing workshops for all bearing components to the production of cages (adjusting production based on the rhythm of cage manufacturing).

Results

- Lead time was reduced from 122 days to 68 days.

- A 44% reduction in work-in-progress inventory and a 21% increase in the output rate of parts.

- Disappearance of the "field hockey stick" phenomenon at the end of the month (3/4 of the production is delivered at the end of the month).

Watch the client's testimonies

Video only available in French

About Marris Consulting

Marris Consulting is an industry consulting and training company specialized in the Theory of Constraints (ToC) and Critical Chain Project Management. We focus on improving the performance of manufacturing and process industries by using Constraints Management combined with Lean and Six Sigma. To boost project performance, we also use Critical Chain Project Management (CCPM), which we sometimes combine with Lean Engineering. Our 2-day performance audits, our performance consulting services and our project management, Lean, ToC & CCPM training by our industry consultants offer a wide range of solutions to help our clients around the world reach the highest possible levels of performance.