Theory of Constraints, Critical Chain Project Management, Lean : industry consulting & training - Marris Consulting

Improve the management of CAPEX projects and reduce the turnaround time of production equipements in the mining industry

Context

Based in Africa, an open pit gold mine decided to increase the production output of its critical equipments, the bottlenecks.

The mine consists in an open pit and a plant which transforms the ore into gold bars.

About 40 dumper trucks ensure the transportation of the raw material from the pit to the plant.

The ore is crushed and grinded in enormous machines, then the resulting muds are treated with chemicals to extract the gold particles.

Increasing production capacity required upgrading the existing equipment and installing new ones.

It is also required to ensure a faultless supply of ore to the plant, which depends on the excellent availability of the trucks and excavators.

Approach

To manage this important project and the related maintenance improvements required to increase production capacities, the company decided to use the Critical Chain Project Management approach :

- The new equipment must be procured and installed.

- 30 pieces of equipment have to be transported from all over the world to the mine, in the middle of the desert.

- Some equipment required important civil works.

- The equipment had to be built and installed on-site.

- The Maintenance teams wanted to improve their performance to increase equipment and machines availability.

Testimony from Stéphane Castillo, project manager at IAMGOLD

Video in French with available english subtitles

Project 1 : Mill Upgrade

-

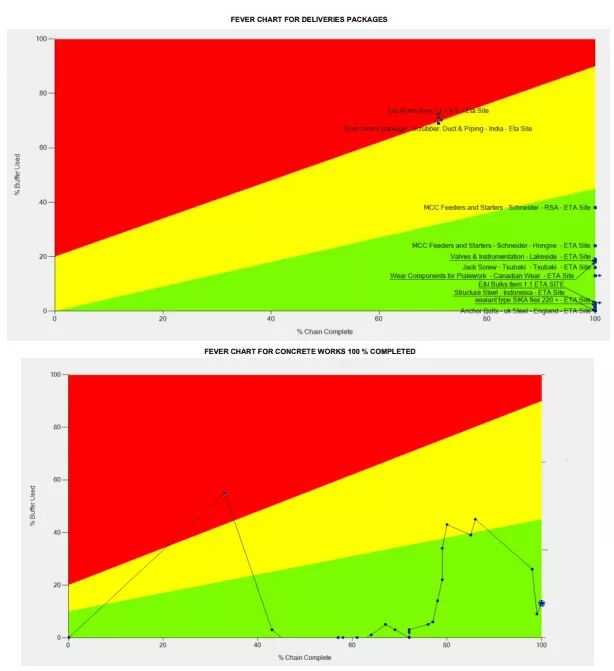

The first phase consisted in supplying all the pieces of equipment from all over the world. These long-delivery time items were managed with Critical Chain. The Fever Chart enabled to track each order and identify the items at risk.

-

The second phase consisted in civil works to prepare the installation of some of the new equipment.

-

The third and last phase was the installation of the new machines.

Project 2 : Maintenance of the mobile equipment

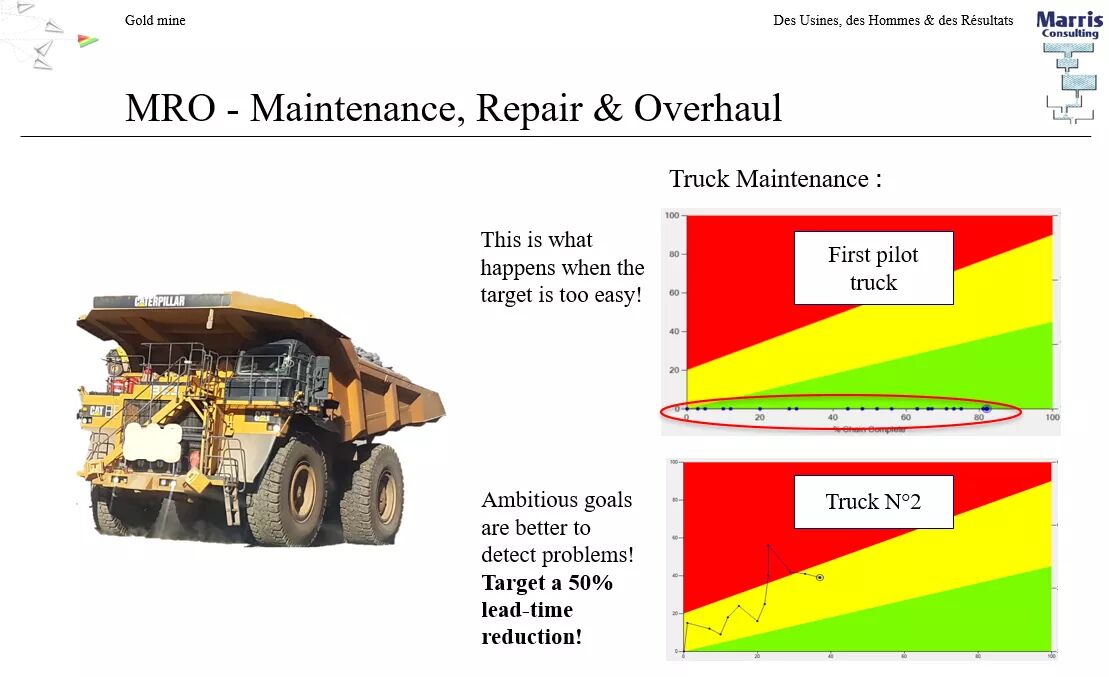

The trucks and shovels are maintained, repaired and overhauled on-site. Increasing the availability of these machines will be critical to enable a smooth supply of the ore from the pit to the plant, and therefore it was decided to use the Critical Chain approach to manage the longest maintenance projects.

The planners were trained to the method and to the tool, as well as the managers and the chief operators. Pilot projects were then initiated.

The first projects revealed that important wastes and margins were extending project durations: the Fever Chart remained in the green zone most of the time. So the decision was made to be more ambitious and to cut the planned duration by half. The project is still on-going, but the first results put forward bottleneck issues that were previously neglected, e.g resources spread thin between too many projects and lack of management and experts availability.

Project 3 : Maintenance of fixed equipment

Increasing the production capacity of the plant is also derived from a better exploitation of the machines and processes. So Management decided to use Critical Chain to prepare and manage the planned maintenance of the critical machines (such as the crusher).

The planners are trained and the project is still on-going.

About Marris Consulting

Marris Consulting is an industry consulting and training company specialized in the Theory of Constraints (ToC) and Critical Chain Project Management. We focus on improving the performance of manufacturing and process industries by using Constraints Management combined with Lean and Six Sigma. To boost project performance, we also use Critical Chain Project Management (CCPM), which we sometimes combine with Lean Engineering. Our 2-day performance audits, our performance consulting services and our project management, Lean, ToC & CCPM training by our industry consultants offer a wide range of solutions to help our clients around the world reach the highest possible levels of performance.