Theory of Constraints, Critical Chain Project Management, Lean : industry consulting & training - Marris Consulting

Demand Driven MRP - The future of MRP

Supply Chain have undergone 40 years of mutations

The business world evolved since the 1970 :

-

Supply Chains are now constituted of large networks of actors;

-

Products' lifespan decreased;

-

Clients demand increasingly low delays;

-

Products are more customized and diversified;

-

But numerous parts require long replenishment delays (distant suppliers)

-

etc.

Companies have to cope with increasing complexity and uncertainty as they face the same symptomatic hurdles: delivery delays, shortages, long lead times, permanent stage of emergency, unreliable previsions, etc.

However, companies continue to use a 40 year-old material requirement systems known as MRP (Material Requirement Planning), though all the problems mentioned above put forward that MRP is no longer adapted to this "New Normality".

Demand Driven MRP, or DDMRP, an adequate response to the "New Normality" Challenge

Time had come for a new alternative to emerge in order to satisfy the requirement supply chains must fullfil, and Demand Driven Material Requirement Planning (DDMRP) has many qualities to adapt Supply Chain Management to the 21st century.

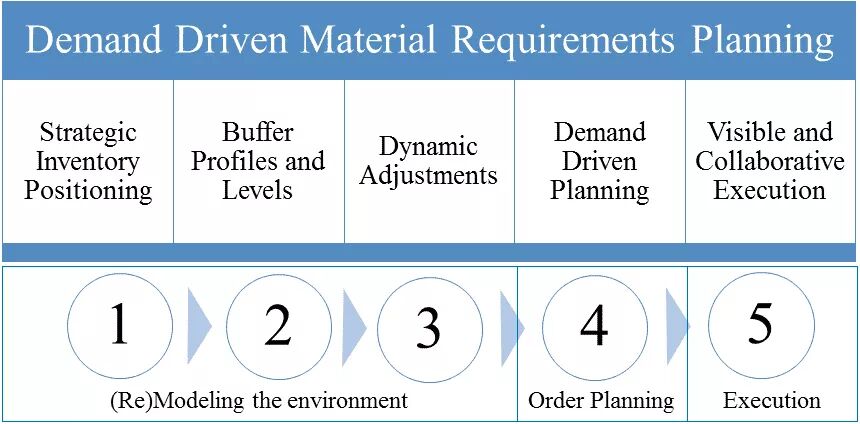

The DDMRP methodology combines principles coming from MRP, Lean, Theory of Constraints and 6 Sigma, and is deployed following a 5 steps process:

1. Strategic inventory postioning

Which items should be stocked? DDMRP takes into account 6 factors to define what should be stocked. One of the most important concepts is "decoupling". It consists in positioning inventory adequately to decouple the client's demand and the supply process : the different items do not concern a particular order. DDMRP is based on the idea that inventory is not only a liability but sometimes an asset: when positioned on the right place at the right moment they enable to avoid the propagation of variability throughout the supply chain, to manage production and orders, and to ensure a minimum lead time;

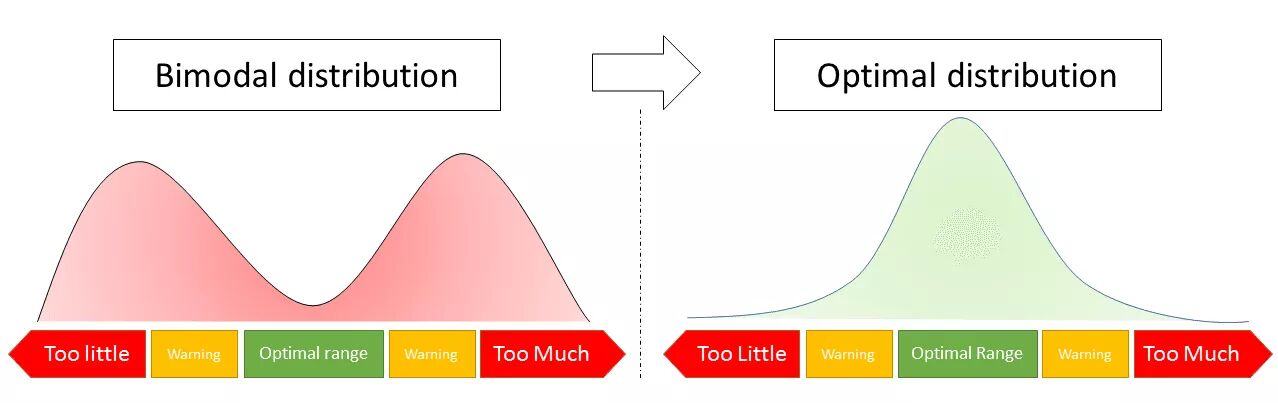

This picture illustrates the fact that too often supply chains hold too little or too much inventory, while DDMRP enables to stock the adequate quantity.

This picture illustrates the fact that too often supply chains hold too little or too much inventory, while DDMRP enables to stock the adequate quantity.

2. Buffer profiles and levels

Define the right size of the buffers (divided into 3 zones: green, yellow and red), that's to say the levels of inventory or margins required in function of replenishment delays, variability and minimum order quantity for instance.

3. Dynamic adjustments

Redefine the size of the buffers regularly.

4. Demand Driven Planning

Anticipate inventory levels according to current supply orders, current inventory and actual ordrers over a specified period, so that new supply orders are generated appropriately.

5. Demand Driven Execution

Order and Produce in function of items' availability. Priority definition is facilitated and collaboration is encouraged. DDMRP favors on-going improvement.

The 5 steps of the DDMRP operation process

The 5 steps of the DDMRP operation process

Results of DDMRP

According to the Demand Driven Institute, the Demand Driven MRP method enabled to obtain the following results :

-

OTD increases by about +100%.

-

Lead Times reduction: -80%

-

Inventory reduction : -30% to -45%

-

Supply Chain Cost reduction : reducing costly expediting (airlift, partial shipment, etc...)

Marris Consulting can carry out a 2-day diagnosis of your Supply Chain or of your production.

Getting started with Demand Driven Material Requirements Planning (DDMRP)

Ready to get started with Demand Driven Material Requirements Planning (DDMRP) for your company? As operational excellence experts, Marris Consulting supports companies wishing to reduce lead times, optimize inventories and improve customer satisfaction by guiding them through the DDMRP methodology.

Demand Driven MRP is a supply chain planning method aiming to improve supply chain performance and optimize production planning by focusing on the flow to protect it from variability, while synchronizing it with the market. As its name suggests, DDMRP is based on demand-driven flow: if the market isn't ready to buy what you have in your flow, your company will waste resources and continue to produce inventory.

Demand Driven Material Requirements Planning combines some aspects of Material Requirements Planning (MRP) and Distribution Requirements Planning (DRP) with Lean, Six Sigma and Theory of Constraints, while adding key innovations to resolve conflicts between different approaches and achieve rapid results.

In conclusion, the benefits of DDMRP in supply chain are numerous when using the right methods to implement it. With over 25 years of experience working with organizations worldwide, our consultants can support your teams in the implementation of Demand Driven Material Requirements Planning, and help your company become more competitive. For more information about our DDMRP consulting services, please do not hesitate to contact our teams.

About Marris Consulting

Marris Consulting is an industry consulting and training company specialized in the Theory of Constraints (ToC) and Critical Chain Project Management. We focus on improving the performance of manufacturing and process industries by using Constraints Management combined with Lean and Six Sigma. To boost project performance, we also use Critical Chain Project Management (CCPM), which we sometimes combine with Lean Engineering. Our 2-day performance audits, our performance consulting services and our project management, Lean, ToC & CCPM training by our industry consultants offer a wide range of solutions to help our clients around the world reach the highest possible levels of performance.